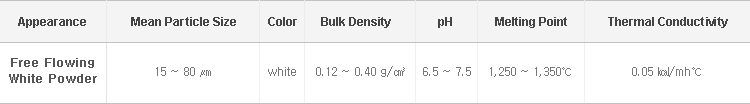

Characteristics

Quantity increase effect

Onyxell is a bead cell whose inside is filled with air, and it increases the quantity to 4 to 5 times only with an amount equivalent to 20 to 30% of existing general fillers.

Heat resistance, flame retardancy and insulation

Onyxell is a natural organic mineral-based ceramic material, and it does not undergo any physical changes even at an extremely high temperature of over 1,100℃, providing outstanding flame retardancy.

In addition, its closed hollow sphere structure delivers outstanding thermal insulation performance.

Chemical stability

As Onyxell is a 100% mineral-based material with a pH value of 7, it has outstanding chemical stability, such as inertness, acid resistance, alkali resistance, etc.

Whiteness

As Onyxell is made of materials similar to glass, it has a high reflectance against external light. In addition, as its raw materials themselves feature excellent whiteness, Onyxell does not affect the chromaticity of raw materials when it is used as a filler.

Dispersibility

As Onyxell is a non-oriented globular filler with a height to width ratio of nearly 1:1, the external force applied to it is uniformly dispersed, resulting in enhanced strength.

What is perlite?

Perlite is an ultralight pure inorganic material that is manufactured by taking an amorphous mineral formed in the process of concentration of the volatile content of magma as it is rapidly cooled while it flows in the ground water, lake or sea, grinding it to an appropriate grain size and then rapidly heating and expanding the grinded mineral at an extremely high temperature over 1,100℃.

High-Performance Filler?

The plasticity expansion technique is the core part of perlite technology. Ultrafine hollow body manufactured using an industry-leading perlite plasticity expanding technology is widely used as caulking and sealing material thanks to its outstanding dispersibility, or as functional weight material for composite materials such as plastic to reduce product weight and improve the flame retardancy and insulation of a product, expanding the range of product use.

Chemical Composition of Perlite

| Components | SiO2 | AI2O3 | K2O | Na2O | Fe2O3 | CaO | MgO |

|---|---|---|---|---|---|---|---|

| Content (%) | 70~75 | 12~16 | 1~4 | 2.5~5 | 0.15~1.5 | 0.1~2.0 | 0.2~0.5 |

The SiO2 contained in perlite is amorphous silica, which is harmless to the human body.

Surface Treatment Features

| Classification | Kind | Use |

|---|---|---|

| Provides water repellency properties |

Silicone, methyl, octyl silane, phenyl silane coating |

Thermal insulation materials, heat insulation bands, thermal insulating waterproofing items and other construction materials |

| Provides organic properties | Methacrylic group, vinyl group, amino, epoxy silane coating |

Organic materials such as coatings, adhesives, plastics, etc. |

| Provides chemical properties | Vinyl group silane, various catalyst coating | Products requiring chemical initiation reaction |

| Provides complementary performance such as strength |

Metal coating such as titanium or alumina | Metal products requiring lightweight |

Applications

Cosmetics, refractory insulating coatings, plastic composite materials, construction putty, tile adhesives, EMX explosive sensitizer, etc.

.jpg)

.jpg)

.jpg)

.jpg)