(1).png)

UL

What is UL?

UL stands for Underwriters Laboratories, which was founded in 1894 and is one of the representative non-profit certification authorities in the US in the field of industrial safety. UL establishes various safety standards and grants certifications, and is one of the most authoritative safety certification authorities.

Esscoat UL is a product that was developed with the goal of obtaining UL certification, and has secured a level of product competitiveness that differentiates it from other existing products.

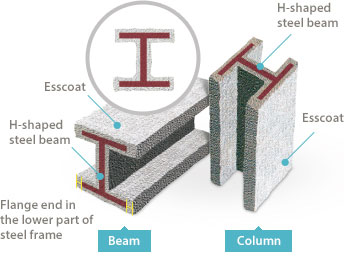

- Esscoat UL is the first of the refractory structure products certified by Korea Institute of Construction Technology to pass 3-hour refractory testing with a test result of below 30mm (29mm).

- Esscoat UL has implemented the minimal coating thickness with the highest level of performance of any UL certified product worldwide.

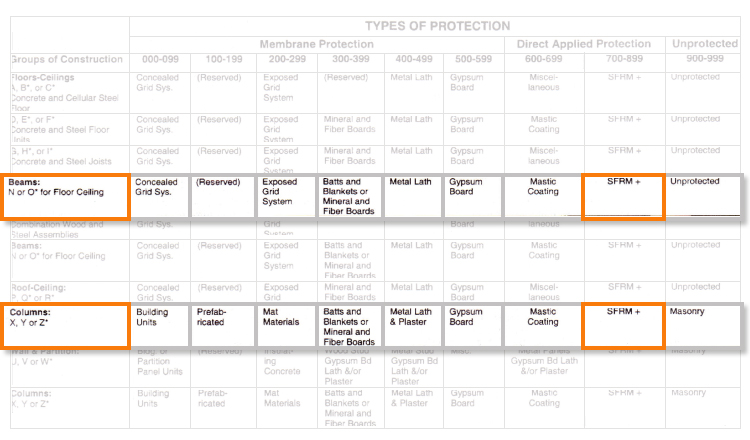

What is UL263?

UL263 is the “Fire Test of Building Construction and Materials.” Of the various refractory materials, coating materials such as Esscoat are classified into the SFRM (Spray-Applied Fire Resistive Materials) category.

Details of UL certification

Comparison between Korea's refractory structure certification and UL263

| Test method | Type of member of frame-work | Nominal dimensions | Coating thickness by refractory time | Remarks | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Detailed guidelines for refractory structure certification and control activities* | Beam | 400㎜ x 200㎜ | 12 | 22 | 32 |

-Non-load-bearing -Unrestrained at both ends -10% increase compared to the requested thickness |

||||

| Column | 300㎜ x 300㎜ | 12 | 22 | 32 | ||||||

| UL 263** | Beam | Min. W8 x 28 | 9 | 13 | 18 | 23 | 27 | 32 | 36 |

-Test is performed by producing a structure in which beams and slabs are integrated. -Under the maximum load -Restraint on both ends (the number in brackets is an unrestrained thickness) |

| (9) | (15) | (20) | (26) | (31) | (36) | (44) | ||||

| Column | W6 x12 | 22 | 30 | 37 | 45 | 52 | 59 | 66 |

-Test is performed by producing a structure in which beams and slabs are integrated. -Under the maximum load -Restraint on both ends (the number in brackets is an unrestrained thickness) -Constant correlation between the coating thickness and refractory time must be calculated. |

|

| W6 x9 | 21 | 28 | 35 | 42 | 49 | 57 | 64 | |||

| W8 x 28 | 19 | 26 | 33 | 39 | 46 | 53 | 59 | |||

| W8 x 16 | 19 | 25 | 31 | 38 | 44 | 50 | 57 | |||

| W10 x 49 | 17 | 23 | 29 | 35 | 41 | 48 | 53 | |||

| W21 x 73 | 16 | 22 | 27 | 33 | 38 | 44 | 50 | |||

| W12 x 106 | 14 | 18 | 23 | 27 | 32 | 37 | 41 | |||

| W14 x 233 | 3 | 13 | 17 | 20 | 23 | 27 | 30 | |||

| W14 x 730 | 3 | 5 | 5 | 5 | 8 | 10 | 11 | |||

UL263 certification process on steel frame beams and pillars

| Beam |

1. The results of refractory testing for 1 to 4 hours on a structure, which is produced by integrating beams and deck plates and then pouring concrete, should show consistent trends. 2. Each end of a beam to be refractory tested should be restrained under the maximum load that can be borne by the test structure. |

|---|---|

| Column |

1. Unlike in Korea, different refractory coating thicknesses should be applied to pillars of various sizes for refractory testing, which is performed for 1 to 4 hours. 2. Properties of coating materials, such as specific heat, density and heat conductivity, should be measured, and a refractory simulation should be performed based on the measured results. 3. Test results will be accepted only when the actual refractory test results and the simulation results using property values match each other. In this case, a formula to calculate the coating thicknesses of all kinds of members of framework can be obtained. |

.jpg)

.jpg)

.jpg)

.jpg)